This article details our entire process for sourcing, producing and delivering our Peak Power Dog Treat products. We want to be as transparent as possible with our processes so that customers have confidence we are producing high quality products that demonstrate the utmost in care and concern for livestock, land, environment and the health of our dogs.

End to End Ownership of the Process

One of the biggest difference between what we do and what most other dog food companies do is that we own the process, from sourcing the ingredients direct from ranches, to production, marketing, sales, direct-to-consumer shipments and finance. The norm for consumer packaged goods companies is to outsource most parts of the business and usually just retain the marketing, sales and finance functions. This means there is much less visibility into the pieces of the business and because they are outsourced, there is much less ability to change those functions because they are owned by another company.

Ranch and Slaughterhouse Selection Criteria For Peak Power Dog Treats

The meat we use for Peak Power Dog Treats comes from Colorado ranches that we personally visit and inspect. It is the same meat that we consume ourselves and feed to our dogs in their home-prepared raw dog food. We have been purchasing from several of these ranches for years.

Another big difference between us and most other dog food companies is that all of our meat is 100% grass fed cows grazed on grasslands and is free of hormones, antibiotics and genetically engineered plants. The cows we purchase are grazed almost exclusively on grasslands year-round. Some of our ranches may need to supplement with hay that they grow or obtain locally during the winter or when deep snows prevent cows from feeding directly on the grasslands.

The ranches we purchase from adhere to the American Grassfed Association standards and have at least a Step-4 or higher rating from the Global Animal Partnership. It is costly to apply for and obtain certification from these organizations, so some of our ranches do not have the official certifications, in which case we do our best to interview and certify for ourselves whether the ranch is adhering to the standards set forth by these organizations.

Since between 94% and 97% of all beef in the U.S. is grain fed feedlot and not grass fed pasture, the vast majority of pet food companies cannot comply with the standards from American Grassfed Association and Global Animal Partnership.

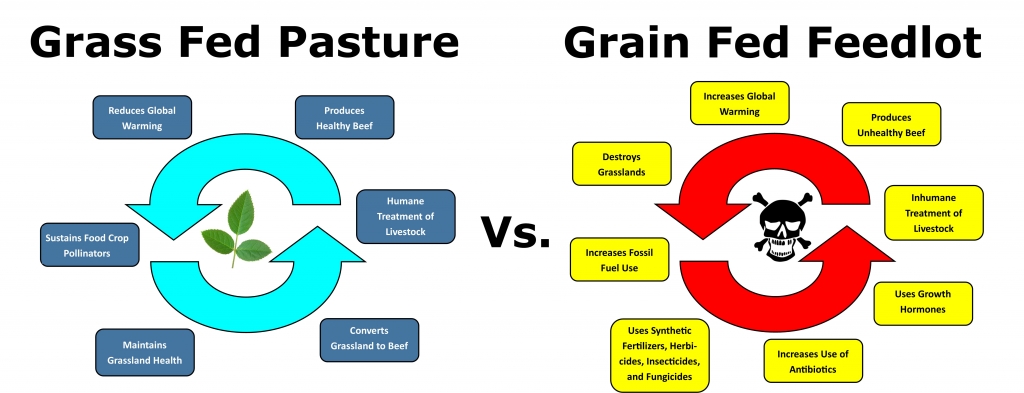

We wrote a detailed article on the differences between grass fed pasture and grain fed feedlot livestock meats, with some surprising (and a little shocking) conclusions. Figure 1 from that article provides a high level summary.

FIGURE 1

Grass fed pasture versus grain fed feedlot

We never purchase meat from wholesalers, distributors, meat brokers or any other middleman. We place orders directly with our ranches and pay them directly for the meat that we purchase.

We have to place orders and deposits at least six months in advance of receipt of the meat. All of our ranches always sell out their beef, so we cannot expect volume pricing because demand is too strong. We also cannot order all of our product from one ranch. Our ranchers have other customers that they want to sell to, so we cannot be their sole customer.

It is also prudent for us to diversify across ranches so that if one ranch has a problem with meeting delivery, we have other ranches we can purchase from.

How do other dog food companies source their ingredients?

Peak Power Dog Treats is a beef-based product, so we want to limit comparisons to other beef-based dog food products.

As we indicated above, the majority of beef-based dog food sold sources grain fed feedlot meats, given that between 94% and 97% of all beef in the U.S. is grain fed feedlot beef. Based on this, almost all dog food products sold have ingredients of inferior quality and concern for livestock and environment compared to our Peak Power Dog Treats.

As we also indicated above, most dog food companies, even small ones that we know of, outsource their production to 3rd party companies who own the facilities and run the production process. This lack of direct control means that the brands you are purchasing from not only do not know what goes on in production plants, but also are much less able to affect the process. Problems with the product are often not noticed until they are being sold to consumers, which by then makes it hard to do anything but recall products. If we have a problem anywhere in our company, we can make changes quickly before product is shipped and sold.

If you wish to know more about how we choose food for our dogs and what we consider quality dog food, please see our resource guide, How To Choose Food For My Dog

Slaughterhouse Selection Criteria

We work with our ranchers and the small USDA licensed slaughterhouses they are accustomed to using and to date, have not had any reason to ask our ranchers to use a different USDA licensed slaughterhouse. We are most concerned with using smaller slaughterhouses that are as close to the ranch as possible to minimize transport time of the cattle from the ranch to the slaughterhouse. This puts much less stress on cattle. It is common for cattle to be transported over great distances. In fact, our animal welfare standards that we use in working with ranches limits transport time to 8-hours, and we feel that is too long. Imagine a cow (or you!) standing for 8-hours in a cramped trailer.

Our slaughterhouses and our jerky production environment on our farm are very small operations, producing Peak Power Dog Treats in small batches. We nor our slaughterhouses are immune from salmonella or other pathogens contamination, but small facilities like ours and our slaughterhouses may have an easier time preventing it because the equipment and environment is just easier to clean, as it is not so big. One well-know, large Canadian dog food brand that has a reputation for quality dog food brings in more than 10-semi trailer truckloads a day of meat to its plant! Just think what 10-semi trailer truckloads looks like and the massive equipment and facilities required to process that much dog food every day, and what must go into cleaning such a large facility.

We pick up from and take possession of frozen meat directly from the slaughterhouse, again, not middleman or transport providers. Some of our slaughterhouses have onsite freezer storage, which we utilize from time to time depending upon how much available freezer storage space we have on our farm.

Cooking And Storing Facilities and Processes for Peak Power Dog Treats

We store frozen raw meat from our slaughterhouse in our freezers at the farm. If we do not have available space to store raw meat, we utilize onsite freezer storage at our slaughterhouses.

We have our own small commercial kitchen licensed by the USDA that we built on the farm specifically to process our commercial food products. It's a small space and we produce in small batches. The Light of Dog commercial kitchen is also a part of and opens up into a large multipurpose room we use for training, boarding, processing shipments and other activities for the business.

An Inside Look at Dog Treat Production

To give you some basis for comparison, we'll compare our cooking and drying process to what we see in all other treat products that we know of.

Dog treats are made with 3 considerations in mind: safety, convenience, health

Safety

Meat has pathogens in it and regulations for making commercial dog food and treats are very strict in eliminating pathogens because of the potential to cause harm to people, not necessarily dogs. The main pathogens in raw meat that are of most concern are salmonella, e.coli and listeria. In general, for healthy dogs, these pathogens are not a problem because their digestion is designed to accommodate pathogens, except for listeria, which can be very dangerous to dogs and humans. These pathogens are killed during cooking in temperatures greater than 160 degrees (or 165 for chicken and pork).

For raw foods or freeze dried foods that are not cooked, one manufacturing process to kill pathogens is irradiation, a process whereby food is subjected to ionizing radiation to attack bacteria by breaking chemical bonds in molecules. It does not result in radioactive food, but it does increase the free radicals and has shown to reduce nutritional values of food in the same way that cooking does.

Another manufacturing process to kill pathogens in raw for freeze dried foods that are not cooked is called high pressure processing (HPP). HPP is a process whereby food is subjected to intense pressure, which kills pathogens. But HPP also breaks apart protein just like cooking, so in our opinion, based on the information we have seen about HPP, there is not any difference between food treated with HPP and cooked food. Both still break apart protein, making it less healthy compared to raw food.

Electrolyzed water is a relatively new process in the U.S. that uses a special water whose chemical composition has been changed through the use of electricity. The ingredients are soaked in this water to eliminate pathogens. This seems like a viable solution to us, but we have not seen nutritional studies comparing electrolyzed food to raw food, so we cannot yet trust that it is a viable process for retaining the health of meat.

There may be other manufacturing processes that kill pathogens which we are not yet aware of.

Convenience

Commercial dog treat products are either dried or freeze dried. Dried food is made by subjecting it to low heat that removes the moisture over a period of time. Freeze drying is rapidly freezing food and then subjecting it to a high vacuum that removes ice by sublimation.

The goal in drying or freeze drying is to remove moisture from food so that it can become more shelf-stable, making it easier to transport and put on a store shelf.

Moisture is the main element that causes food to go bad, either through mold or through certain fats in the food going rancid. Oxygen is another element, but is difficult to eliminate in soft packaged products and even in microscopic amounts, it can cause mold or rancidity. Thus, the goal is to remove moisture.

A product with more moisture in it will spoil quickly outside of the refrigerator, whereas a product with little moisture may be able to remain outside of a refrigerator or freezer for a period of time and still be safe to consume. A shelf life of twelve months is a general goal in commercial shelf-stable treat products.

Meats dried or freeze dried also tend to be limited to lean cuts with as little fat as possible. Meat has a combination of fats – saturated, monounsaturated, and polyunsaturated. The latter two are not as stable at room temperature or exposure to light and go rancid quickly. Yet, they are healthy fats for dogs to eat, unless they are rancid, in which case they are not.

The problem with drying is that when it eliminates most of the moisture, the end product becomes very hard and brittle. But it is hard to work with brittle products, so manufacturers include additional ingredients – preservatives – that help food stay shelf-stable with more moisture so that it is more forgiving to eat or break apart into pieces.

Even if a manufacturer uses genuine grass fed beef, product quality will go down significantly with the use of preservatives. Popular ones are potassium sorbate (salt), tocopherols and glycerine.

The amount of salt needed to preserve meats for shelf-stability is way too high for dogs to tolerate. We see some treat products with packaging instructions that include the recommended maximum amounts of their product that can be fed to a dog per day. This is because of the high salt quantities used.

Tocopherols are anti-oxidents designed to prevent oxidation of fats. Whether they are natural or synthetic or organic, they are by-products of the vegetable oil refining industry, and the cleanup steps applied to the by product “sludge” are quite extensive before it can be used in food. Further, treat manufacturers purchase tocopherols from other manufacturers and the treat manufacturers may not even know the base source product for the tocopherols. It could be soy or other allergens that are not good for dogs to eat.

In addition, over time, with continual exposure to oxygen whenever you open the treat bag (and the bags are not perfect oxygen barriers either), the anti-oxidants are eventually all oxidized (used up) and the fats, beginning with the more fragile ones, start turning rancid. Studies show that frequent consumption of oxidized fats may cause cancer and contribute to many chronic health problems (1).

As a result, shelf-stable products may typically not be not as shelf stable as manufacturers think (2), despite what the best-use-by date says on the packaging. We highly recommend purchasing and using shelf-stable products within 3-months of their manufacture date and when not in use, store the products sealed in their original packaging in the refridgerator (or freezer if not planning to use for an extended period of time).

Glycerine is a processed ingredient designed to encapsulate moisture and not a natural occurring substance in foods. It too can easily come from soy or other allergens.

Health

Because safety and convenience are of most concern in producing dog treat products, the end product is not as healthy and in most cases for shelf-stable products purchased in stores, we think there are unhealthy. As mentioned above, shelf-stable products may not really be that shelf-stable and the best-use-by-date that many tpyical products use, which is 12-months, is far too long (2).

The healthiest product is obviously one that is not cooked at all so as to leave intact the enzymes and protein for dogs to easily assimilate in their digestive tracts. But that would require careful handling from dog owners to ensure that pathogens are not ingested by owners and it is not at all convenient to be handling wet, slimy raw food when dispensing treats.

The Peak Power Treats Process Versus All Other Treats

We started thinking about making our own dog treats in 2013 for our dogs because of this consistent distortion we see across brands – emphasize safety because it is required by law, convenience because that is what most consumers want, and healthy product considerations in third position. We started from the basis of safety and healthy product, followed by convenience.

The result is the following:

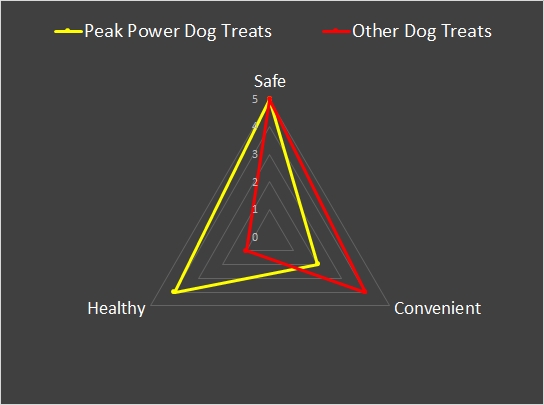

FIGURE 2

Peak Power Dog Treats Versus Other Dog Treats

To be honest, Figure 2 is our opinion and there are no facts representing the numbers in this figure. We want to graphically illustrate where we stand relative to other typical shelf-stable treat products.

Health

We have our slaughterhouse grind a whole animal (minus the organs), which includes all the cuts and beneficial fats of 100% grass fed beef. We do not select out certain cuts with less fat. We use the whole animal in our products. Our cooking and drying process produces a semi-soft, moist product that still retains some beneficial enzymes and is easy to work with, yet not slimy or greasy. Because we add no preservatives, we can ensure a healthy product versus an unhealthy one with preservatives. Obviously, the healthiest product is uncooked, but we could not do that and deliver a safe product, which is why we still rate lower on the healthy scale.

Another area where we may fall a bit in product health is in age of meat. Ground meat can weaken and/or break the cell walls of the ingredients (protein and fats), which will hasten the degradation of the fats and cause them to go rancid quicker. Even in a freezer, they still slowly oxidize. While frozen ground meat is safe to eat, its quality degrades rather quickly – within 4-months as indicated by official government publications for meat stored at 0 degrees F (minus 18 C) (3). According to government publications, this does not mean it is unsafe to eat, but it is less healthy and the longer frozen ground meat is kept, the more rancid the fats become. At some point makes it unhealthy to eat, even though government publications say it is safe to eat indefinitely if stored in a freezer.

Unfortunately we don't know at what point does a ground meat product frozen in the freezer become rancid. We have not been able to locate studies that specifically tell us that. So, to explain the process, the cow is slaughtered and we receive it a few weeks later, ground and frozen. We put the meat in our freezers, which we keep at -5 to -10 F (-20 to -23 C), and then we produce Peak Power Dog Treats with that meat within 6-months of slaughter, often times much sooner, but sometimes it's longer than that. We place orders for our meats twice per year and take delivery of new product every 6-months, so our turnover is typically 6-months. So, on the whole, when we compare the 4-months quality standard to our 6-months time frame, we still think we are delivering a healthy products, but we don't know how much oxidation has occurred because we cannot find any studies telling us that.

Safety

Because we are using pure grass fed beef, we may enccounter fewer issues with E.coli because studies may indicate that grass fed pasture beef is less susceptible to producing resistant E.coli that can survive the acidic conditions of the human stomach (4). Regardless, pathogen testing is done by the slaughterhouse facility to help ensure a safe product.

Because we do not use preservatives and are using the whole cow, which includes all the cuts and beneficial fats of 100% grass fed beef, we require our product to be stored in the refridgerator or freezer when not in use.

Convenience

We have two versions of our product: a semi-soft version that requires climate control and a shelf-stable version.

The shelf-stable version is convenient because it does not need to be climate controlled in a refrigerator or freezer. It is the same product as our semi-soft version, except that it is dried much longer to make it shelf stable. The semi-soft is an ideal training treat because it is soft to work with (but not greasy).

We do not use any preservatives in our shelf-stable version, which means it is very dry and not soft and moist. So compared to a soft and moist training treat, it may be less convenient to work with.

Superior Taste

We've consistently heard from customers that their dogs love our treats. We believe it's for a number of reasons:

- The meat is a blend of the cow with all the beneficial and tasty meat cuts and fats that dogs love;

- The product is fresh without any preservatives, which dogs might smell and dislike;

- The product is fresh and the fats are not rancid or have traces of rancidity, which dogs can smell. Have you ever seen or know of a dog that stops eating their dry food? It is possible it is rancid and not only does the dog find it unpalatable, but it is also very unhealthy to be eating rancid fats (1) (5).

We don't want to be negative about other dog treat companies, but unfortunately, unless they do the research like we have and know at a very detailed level the sources for their ingredients and their production processes, they cannot ensure a healthy product. That is the unfortunate state in which our food system has fallen. It is a daunting process, but one which we undertook to make sure we feed our dogs (and us) healthy food, and we want to ensure that our products have that same level of care and concern for our customers and their beloved pets.

Equipment

All of our cooking is done on stainless steel, including any utensils and cooking accessories.

We try to limit the use of plastics, but we cannot get away from it completely.

We don't use harsh cleaners or chemicals in our kitchen. We use biodegradable soaps and vinegar.

Product Packaging

We do our best to source the most environmentally sustainable packaging we can find.

Our smaller retail packaging is biodegradable plastic packaging that we obtained from an innovative Canadian company, which was declared by the European Union’s Committee on Sustainable Plastics stamp to be “the only viable biodegradable solution available today” compared to all other sustainable films on the market (the EU is much more stringent when it comes to environmental standards than the U.S). The packaging has a resealable top, which is not biodegradable due to technology that as far as we know, is not yet available.

The smaller retail package is not clear like most treat packages we see, so it helps hide the product from light exposure, which quickens the process for turning fats rancid.

Our bulk packaging is 32-ounce glass jars with metal twist lids (that have food grade silicon seals). We encourage purchase of this option because you can clean and reuse the 32-ounce glass jars and we offer discounts when purchasing in bulk. In our household, we save all glass containers that are 25-ounces and larger and re-use to store food for us and our dogs. We have built up quite a collection over the years.

If you wish to know how to read the nutrition label on dog food packaging and compare Peak Power Dog Treats to other products, please see our resource guide, How To Choose Food For My Dog.

Footnotes

1. Brown, Steve (2010-03-03). Unlocking the Canine Ancestral Diet: Healthier Dog Food the ABC Way (Kindle Locations 1601-1604).

2. Brown, Steve (2010-03-03). Unlocking the Canine Ancestral Diet: Healthier Dog Food the ABC Way

Kindle Locations 1768-1773. One of the most important lessons I learned about formulating dog foods was: what can oxidize will oxidize. Many years ago I developed a freeze-dried “raw” food. Freeze drying removes the moisture in a food at low temperatures, thereby preserving most of the nutrients. I packaged the product in a high-barrier-to-oxygen foil bag, and included an oxygen scavenger (one of the small packets often found in vitamin jars) in the bag to absorb the oxygen left in the bag after packaging. Theoretically, I should have had a stable product, with a shelf life of at least one year. But when I tested the product every month for oxidizing fats, I found a steadily deteriorating product. The fats—probably EPA and DHA—were becoming rancid. The defenses against oxidation I utilized were not sufficient.

3. https://www.foodsafety.gov/keep/charts/storagetimes.html

4. Michael Pollan, author of The Omnivore’s Dilemma, states that the lethal strain of E. coli known as 0157:H7 is believed to have evolved in the gut of feedlot cattle. The development of a more acidic environment in cows’ intestinal tracts created an acid-resistant strain of the pathogen, which is able to survive the acidic conditions of the human stomach and prove fatal. In the documentary Food, Inc., Pollan states that switching feedlot cattle to a grass diet would eliminate 80 percent of the E. coli in the cows’ digestive tracts.

and

5, Brown, Steve (2010-03-03). Unlocking the Canine Ancestral Diet: Healthier Dog Food the ABC Way

Kindle Locations 322-329: Advances in packaging have reduced, but not eliminated, the amount of oxygen that is transmitted through unopened dog food bags. Once the bags are opened, air rushes in and accelerates the oxidation of the fats. All the studies and nutrient analyses tests I’ve seen on the DHA content of dog foods were conducted at or very close to the time of manufacturing, when the foods were fresh. The tests were not conducted in time frames that reflect when the dog eats the food, for instance four months after the dog food was manufactured. Such a time frame might well include three weeks in a hot Houston warehouse, and 20 days after the bag has been opened in the dog owner’s sometimes humid kitchen or garage. How much DHA is left under these rough, but typical, conditions? The data I’ve seen suggest little DHA is left, and many of the other fats have also turned rancid. This is especially common when large bags of dry food are opened, but not completely consumed, for several days or even weeks.

Our goal is to positively impact the lives of as many dogs and their families as we can, in part through our extensive library of video, infographics and text articles. |

Hello, where do you source your flours from?

We do not use flour. We use only meats, vegetables and fruits